In many instances intrusive inspection remains the only means of establishing accurate information on the size, type and condition of concealed structure. Where intrusive inspection is necessary, it is carried out using highly skilled operatives utilising non-destructive survey techniques to minimize the size of the intrusive inspection sites.

Reinforced Concrete Detailing

Selected bars are exposed for inspection after first mapping the steel layout using ground penetrating radar and/or covermeters. Only through intrusive inspection can the bar types, sizes and condition be accurately determined.

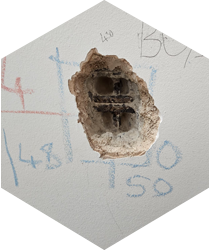

Structural Steel Detailing and Condition Assessment

Steel sections are locally exposed using percussion drills and breakers to carefully remove any encasing materials sufficiently to enable our engineers to assess the condition of the embedded steelwork and to record the section sizes and details of any connections. Assessment as to the extent of loss of section due to corrosion can be made with reference to the original steel section identified from published tables.

Foundation Detailing

Foundations are exposed after locally breaking out any ground slabs and then hand digging trial pits. Ground Penetrating Radar surveys can provide a wealth of information on foundation construction, particularly where the foundations are monolithic with the floor slabs.

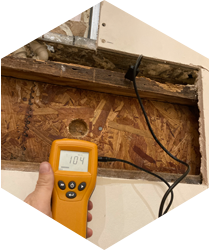

Timber Detailing and Condition Assessment

Concealed timber elements can be located and locally exposed to assess condition, general arrangement, member sizes, spacing and connection details. Insitu testing includes determination of moisture content and internal condition by resistographic drilling.